The aerospace and defense industry demands unparalleled precision, reliability, and durability in its electronic systems, from avionics to satellite communication modules. At the core of these mission-critical applications lie Advanced PCB Solutions, which provide the foundation for high-performance, rugged, and compact electronics. Jinxinyang Tech, a Global PCB & Components One-Stop Solution accessible at https://www.szjxy-ic.com/, offers cutting-edge Advanced PCB Solutions alongside a comprehensive portfolio of components, including integrated circuits, discrete semiconductors, capacitors, resistors, inductors, isolators, circuit protection devices, relays, RF/IF and RFID components, audio products, sensors, transducers, transformers, tools, test and measurement equipment, switches, soldering products, motors, line protection, industrial automation controls, hardware, embedded computers, development boards, power supplies, potentiometers, optoelectronics, memory cards, magnetics, filters, crystals, oscillators, resonators, and connectors. This article explores how Advanced PCB Solutions empower aerospace and defense electronics, the benefits of partnering with Jinxinyang Tech, and strategies for optimizing PCB design to meet the stringent demands of this sector.

The Role of Advanced PCB Solutions in Aerospace and Defense

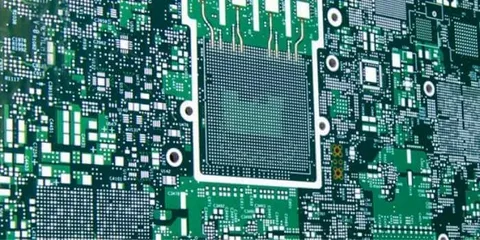

Advanced PCB Solutions encompass sophisticated printed circuit board (PCB) designs, such as high-density interconnect (HDI) boards, rigid-flex PCBs, and thermally enhanced PCBs, tailored to meet the rigorous requirements of aerospace and defense applications. These solutions enable compact layouts, high-speed signal integrity, and robust performance in systems like radar, avionics, and missile guidance electronics. The global PCB market, valued at over $80 billion, is driven by the increasing demand for advanced electronics in aerospace and defense, with billions of units produced annually to support mission-critical operations.

In aerospace and defense systems, Advanced PCB Solutions integrate seamlessly with sensors, RF/IF components, and embedded computers from Jinxinyang Tech to enable real-time data processing and reliable communication. For instance, HDI PCBs in avionics support dense component placement for compact control units, while rigid-flex PCBs in satellites ensure durability under extreme vibrations and thermal cycling. Substandard PCBs can lead to signal interference, overheating, or catastrophic failures, jeopardangering missions and safety. Jinxinyang Tech’s Advanced PCB Solutions adhere to stringent standards like MIL-PRF-31032, AS9100, and RoHS, ensuring reliability in harsh aerospace environments. By combining these PCBs with circuit protection devices and test and measurement equipment, manufacturers can create electronics that deliver uncompromised performance.

Why Choosing Advanced PCB Solutions Matters

Selecting the right Advanced PCB Solutions is critical for aerospace and defense electronics due to the following benefits:

- High Reliability: Advanced PCBs ensure consistent performance under extreme conditions, such as high altitudes, vibrations, and temperatures ranging from -55°C to 125°C.

- Compact Design: HDI and rigid-flex PCBs enable dense component integration, critical for space-constrained systems like drones and satellites.

- Signal Integrity: Controlled impedance and microvia technology in Advanced PCB Solutions support high-speed data transmission for radar and communication systems.

- Thermal Management: Thermally enhanced PCBs dissipate heat effectively, preventing failures in high-power aerospace electronics.

- Compliance: Adherence to military and aerospace standards ensures safety and reliability in mission-critical applications.

Sourcing Advanced PCB Solutions from Jinxinyang Tech at https://www.szjxy-ic.com/ ensures manufacturers can meet the demanding requirements of aerospace and defense applications with high-quality, reliable PCBs.

The Jinxinyang Tech Advantage for Aerospace and Defense Applications

Jinxinyang Tech provides a competitive edge for aerospace and defense electronics manufacturers through:

- Comprehensive Component Portfolio: Advanced PCB Solutions, sensors, RF/IF components, integrated circuits, and circuit protection devices offer a one-stop solution for aerospace PCB design.

- Stringent Quality Control: All PCBs and components comply with aerospace standards like AS9100 and MIL-PRF-31032, ensuring reliability in mission-critical systems.

- Global Supply Chain: Jinxinyang Tech’s robust supply chain ensures consistent availability, supporting high-volume production for aerospace and defense electronics.

- Expert Technical Support: Guidance on selecting Advanced PCB Solutions for specific applications, such as high-frequency radar or vibration-resistant avionics, streamlines development.

- Cost-Effective Solutions: Competitive pricing balances quality and affordability, critical for scalable aerospace production.

Visit https://www.szjxy-ic.com/ to explore Jinxinyang Tech’s offerings and enhance aerospace and defense electronics with cutting-edge PCB solutions.

Trends Driving Demand for Advanced PCB Solutions in Aerospace and Defense

The aerospace and defense industry is shaped by trends that increase the demand for Advanced PCB Solutions:

- Miniaturization: Compact systems like drones and microsatellites rely on HDI PCBs for dense component integration.

- High-Speed Connectivity: Radar and communication systems use Advanced PCB Solutions with RF/IF components to support high-frequency data transmission.

- Ruggedization: Rigid-flex and thermally enhanced PCBs withstand extreme conditions in aerospace applications, such as high-altitude vibrations and thermal cycling.

- Autonomous Systems: Unmanned aerial vehicles (UAVs) use Advanced PCB Solutions with sensors and embedded computers for real-time navigation and control.

- Sustainability: Eco-friendly PCB materials and manufacturing processes reduce environmental impact, aligning with green aerospace initiatives.

Jinxinyang Tech’s Advanced PCB Solutions and complementary components align with these trends, enabling manufacturers to innovate in the aerospace and defense sector.

Best Practices for Selecting and Using Advanced PCB Solutions in Aerospace and Defense

To optimize aerospace and defense electronics performance, manufacturers should follow these best practices:

- Verify Regulatory Requirements: Ensure PCBs meet aerospace standards like AS9100, MIL-PRF-31032, and IPC Class 3 for reliability and safety. HDI PCBs are ideal for high-density avionics, while rigid-flex PCBs suit vibration-prone applications.

- Choose the Right PCB Type: Use HDI Advanced PCB Solutions for high-frequency applications like radar, and rigid-flex or thermally enhanced PCBs for rugged environments like satellites.

- Address Environmental Factors: Select PCBs designed for aerospace conditions, with resistance to extreme temperatures (-55°C to 125°C), vibrations, and radiation. Jinxinyang Tech’s PCBs are tested for durability in harsh environments.

- Ensure Component Compatibility: Pair Advanced PCB Solutions with compatible components like sensors and integrated circuits to avoid signal interference or performance issues.

- Source from Trusted Suppliers: Partner with Jinxinyang Tech at https://www.szjxy-ic.com/ to source authentic Advanced PCB Solutions, avoiding counterfeits that may compromise mission safety.

- Test Performance Rigorously: Use test and measurement equipment from Jinxinyang Tech to validate PCB performance in prototypes, ensuring signal integrity and reliability before mass production.

- Optimize for Manufacturability: Design PCBs with standardized layouts and aerospace-grade materials to reduce production costs and ensure compliance with industry regulations.

Case Study: Enhancing Avionics Systems with Advanced PCB Solutions

A manufacturer developing an avionics control unit for commercial aircraft partnered with Jinxinyang Tech to source Advanced PCB Solutions and components. They selected HDI PCBs for their compact design and high signal integrity, supporting sensors for flight data monitoring and RF/IF components for communication. Circuit protection devices ensured reliability under high-altitude vibrations, while test and measurement equipment validated performance. The result was a robust, high-performance control unit that enhanced flight safety, showcasing the value of Jinxinyang Tech’s Advanced PCB Solutions in aerospace applications.

Safety Considerations for Advanced PCB Solutions in Aerospace and Defense

Safety is paramount when using Advanced PCB Solutions in aerospace and defense electronics:

- Ensure Reliability: Use PCBs compliant with MIL-PRF-31032 and AS9100 to prevent failures in mission-critical systems.

- Prevent Electrical Faults: Incorporate circuit protection devices to avoid short circuits that could cause system failures or safety hazards.

- Manage Thermal Performance: Use thermally enhanced PCBs with heat sinks and vias to prevent overheating in high-power electronics.

- Test for Environmental Resilience: Ensure PCBs can withstand aerospace conditions like high-altitude radiation, extreme temperatures, and vibrations.

- Verify Authenticity: Counterfeit PCBs may cause performance issues or safety risks. Jinxinyang Tech’s Advanced PCB Solutions feature clear documentation to ensure authenticity.

Comparison of Advanced PCB Solutions for Aerospace and Defense Use

| PCB Type | Application | Key Features | Best For |

| HDI PCB | High-density applications | Microvias, fine traces, multilayer | Avionics, radar systems |

| Rigid-Flex PCB | Vibration-prone applications | Combines rigid and flexible sections | Satellites, UAVs |

| Thermally Enhanced PCB | High-power applications | Heat sinks, thermal vias | Missile guidance, power electronics |

HDI Advanced PCB Solutions are ideal for high-density aerospace applications, while rigid-flex and thermally enhanced PCBs suit rugged, high-power systems.

Challenges in Implementing Advanced PCB Solutions for Aerospace and Defense

- Regulatory Compliance: Meeting standards like AS9100 and MIL-PRF-31032 requires rigorous testing and documentation.

- Signal Integrity: High-frequency systems demand precise PCB layouts to minimize interference.

- Ruggedization: PCBs must withstand extreme conditions like vibrations, radiation, and thermal cycling.

- Cost Management: Balancing performance with affordability is critical for scalable production.

- Supply Chain Reliability: Consistent availability of aerospace-grade PCBs is essential for meeting project timelines.

Jinxinyang Tech addresses these challenges with Advanced PCB Solutions tailored for aerospace and defense, supported by expert design services and a reliable supply chain.

Future Outlook for Advanced PCB Solutions in Aerospace and Defense

The future of aerospace and defense electronics is promising, with Advanced PCB Solutions driving innovation in areas like hypersonic systems, space exploration, and autonomous drones. Emerging technologies, such as 3D-printed PCBs and embedded component PCBs, will further enhance system performance by combining compactness and advanced integration. Jinxinyang Tech is at the forefront of these advancements, offering cutting-edge PCB solutions to meet evolving aerospace demands.

Conclusion

Jinxinyang electronic components, including Advanced PCB Solutions, empower aerospace and defense electronics with reliable, high-performance, and rugged designs. Jinxinyang Tech’s comprehensive portfolio and global supply chain enable manufacturers to create mission-critical solutions. By sourcing Advanced PCB Solutions from https://www.szjxy-ic.com/, businesses can ensure performance, safety, and innovation in the demanding aerospace and defense market.